-40%

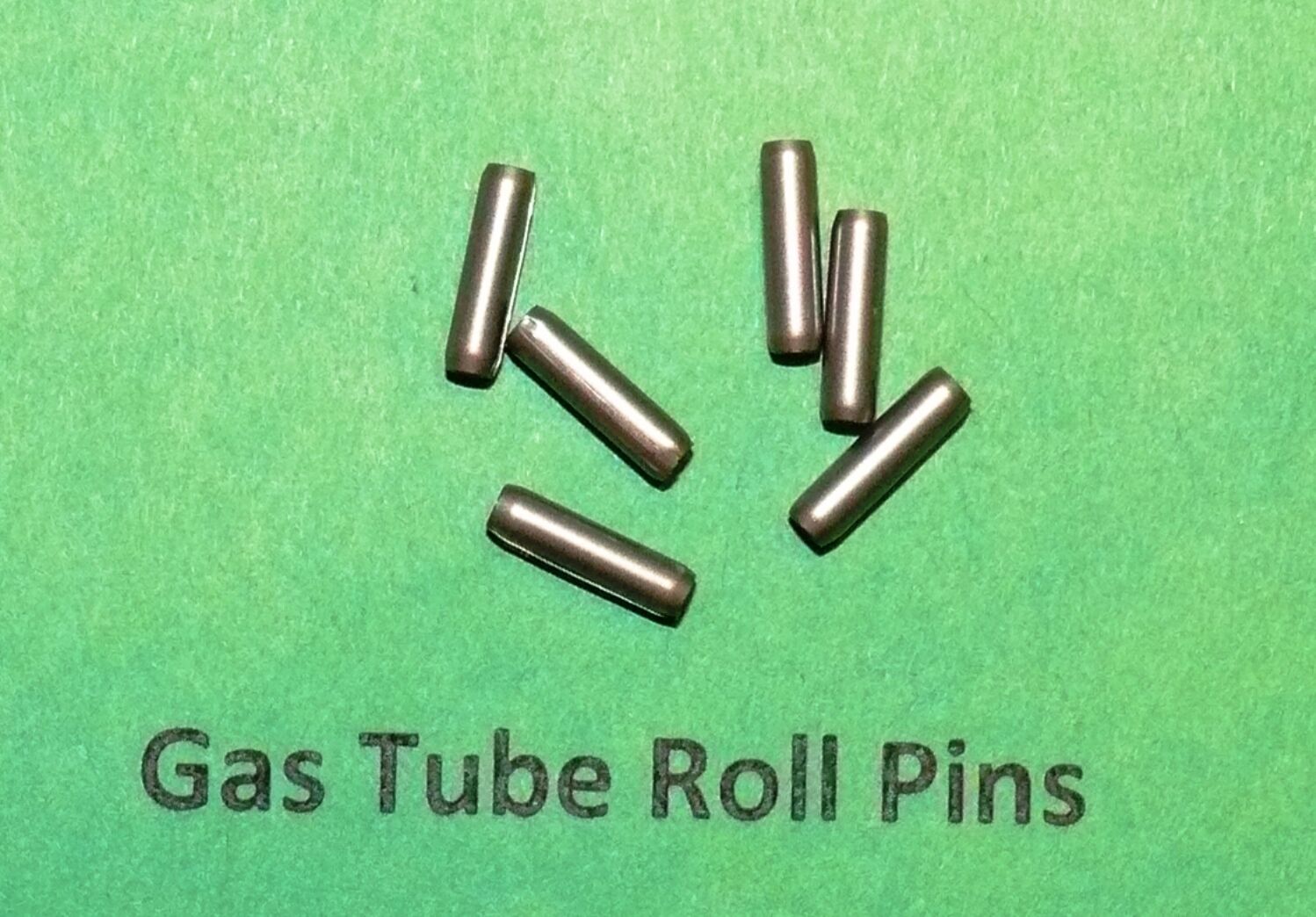

12 5/64" X 5/16" SPIRAL COILED HARD SS GAS SYSTEM ROLL PINS Mil Spec

$ 2.42

- Description

- Size Guide

Description

12 new PREMIUM QUALITY HEAT TREATED, HARDENED Stainless Steel COILED spring pins.COILED PINS ARE SUPERIOR TO THE STANDARD SPLIT ROLL PINS. Â EASIER TO INSERT, EASIER TO REMOVE, AND STRONGER IN USE. Â THEY ARE ALSO MORE LIKELY TO BE REUSABLE WHEN REMOVED. Â THESE ARE 420 SERIES STAINLESS THAT HAVE BEEN HEAT TREATED SO THEY ARE HARD AND EXTRA STRONG.

TRULY THE FINEST QUALITY PINS AVAILABLE FOR THE COLT RIFLES AND ALL CLONES.

Smooth finish on pins make installation easier. Â Corrosion Resistant.

Once you have used these hardened coiled pins, you will never go back to the standard roll pins. Â They are that much better!!

MADE IN USA

YOU WILL RECEIVE A TOTAL OF 12 PINS

FOR THE GAS SYSTEM, .084" DIAM. X .312" LONG

I ship via First Class Mail by the next business day or the same day if order is received before the mail runs.

CENTRALLY LOCATED IN TEXAS FOR QUICKEST NATIONWIDE

SHIPPING

Check my other listing for different quantities

If you need a different quantity listed, ask me. Â I am pretty flexible.

CHECK MY OTHER LISTINGS FOR

SOCKET HEAD Screws

OTHER ROLL PINS FOR COLT RIFLES AND CLONES

Unique Features of Spirol Coiled Roll Pins

Equal Stress Distribution

Stresses imparted to the pin during installation compression as well as stresses resulting from applied loads are distributed equally throughout the pin's cross section. This concept and uniform flexing and strength are related and inherent

features of the spiral design. Stress concentration results in a weak point where progressive shear failure starts and premature fatigue occurs. SPIROL Coiled Pins have no weak points.

Uniform Strength and Flexibility

The shear strength and flexibility of SPIROL’s Coiled Pin is not affected by the direction of force. Compression causes the pin to coil from the outer edge inwardly towards the center. As the pressure is relieved, which happens in shock and vibration, the pin action reverses thereby maintaining a constant radial force. Application of an excessive load results in compression into a solid tube. Further loading causes shear failure. In properly engineered applications, this condition should not occur.

Absorbs Shock and Vibration

The SPIROL Coiled Pin design represents broad design latitude in the control and development of pin flexibility. The engineered flexibility of SPIROL Coiled Pins provides for compression of the pin into the hole and for continued flexibility after insertion. Without this flexibility, the total load applied to the pin would be transmitted to the hole wall without dampening the impact. Since the host material

is normally softer than the pin, elongation or enlargement of the hole would result. The fit between the hole and the pin would become loose, increasing the impact force and accelerating the rate of hole damage. The inevitable result would be premature failure of the assembly. In properly engineered applications, the flexibility of SPIROL Coiled Pins dampens shock and vibration, thus eliminating hole damage to all the components of the assembly resulting in maximum product life.

The smooth, concentric chamfer combined with square, clean-cut ends translates into trouble-free installation. Inward motion from compression Reverse motion when pressure is relieved.

Square Ends

SPIROL Coiled Pins have clean, square cut ends. This has a substantial impact on trouble-free automatic installation as the square ends enable the pin to align itself with the installation punch/quill to ensure the pin remains straight as it is inserted into the hole. The cleancut ends also impart a quality image to the assembly.

Swaged Chamfers

SPIROL Coiled Pins have a smooth, concentric lead-in chamfer with a radius which blends into the diameter of the pin. There are no sharp angles or edges to bite into

the hole wall. The swaged chamfer provides maximum compression leverage with minimum thrust resistance to ease insertion. The chamfer concentricity assists in alignment of holes. Only Coiled Pins utilize the coiled spring concept; a recognized superior pin design. This imparts to

SPIROL

Coiled Pins unique features not found in other Spring Pins or Solid Pins. More than fasteners, SPIROL Coiled Pins are also shock absorbing elements which are integral, active components of a total assembly. There are other pinning methods, but when the total assembly’s manufacturing cost, quality and useful life are important, the pin of choice is the SPIROL Coiled Pin.

Closer Diameter Tolerances

SPIROL

Coiled Pins have a closer diameter tolerance than any other Spring Pin. At least 270° of the outer circumference is within the specified

tolerance range. The minimum diameter is not averaged, as is the case with

other Spring Pins. The edge of the seam is designed to be tucked below

the hole diameter to prevent the edge from contacting the host. These factors

combine to make SPIROL Coiled Pins ideal for hinge, axle, and dowel applications.

Other Advantages

Lower Insertion Pressure – Radial Tension

Standard and light duty SPIROL Coiled Pins require less pressure to insert than other Spring Pins. In addition, these pins exert less radial tension, an important factor where holes are in thin sections or close to an edge. It is also important when using soft, weak or brittle materials such as aluminum or plastic. The benefit is lower component damage and fewer rejects. An added benefit to lower insertion force is insertion machinery can use smaller cylinders, and if manually installed, the assembler is less subject to fatigue or repetitive motion syndrome.

Conforms to Hole

The thin gauge material and the 2ÂĽ coiled construction gives the pin a greater inherent ability to conform itself radially and longitudinally to the hole wall.

It can be used in out-of-round and tapered holes without negatively affecting its performance. SPIROL Coiled Pins develop a mean radial pressure without excessive high points which would result in hole damage upon insertion or under loading. Other types of Spring Pins typically have three points of contact between the pin and

the hole which results in focused stress over a limited contact surface area. On the contrary, SPIROL Coiled Pins maximize contact between the pin and the hole resulting in better load distribution and reduced possibility of hole damage.

Reusable

When driven from a hole, the SPIROL Coiled Pin expands towards its original diameter. The same pin may be reused in the same hole.

Wider Hole Tolerance Range

SPIROL Coiled Pins can be installed in holes with a wide diameter tolerance. Holes can be drilled according to normal shop practices, drills can be used longer, and the feed rate of the drills can be maximized. Drilling can be eliminated completely by utilizing molded, cast, and stamped holes. No secondary hole preparation is necessary to be able to use a Coiled Pin.

Straightness

Although the straightness specifications are technically the same, carbon steel Coiled Pins of longer length in relationship to diameter are straighter than roll-formed

Slotted Pins. The stresses imparted during the heat treating process distort long Slotted Pins into a "banana shape" caused by the material stretching at the slot and c

ontracting 180Âş opposite the slot. Straightness is important in numerous applications and for trouble-free insertion.