-40%

Child Rocker Glider Chair Hardwood Kit Build together with child? COMPL IS AVAIL

$ 41.71

- Description

- Size Guide

Description

My vision when I created these kits was that it could be a project done together with a child. The "labor" is sanding, wiping on stain (or painting), gluing 14 tenons into the pre-made mortises, screwing in 24 screws, and gluing in 24 wood plugs to cover the screws. Then you can pick out (or make) the cushions.HELP? I ask for your help. The "Story" below gives the background, but I'd really like to know what YOU (potential buyer) think.

Why aren't you buying this?

The chair itself is not appealing?

The "kit" is wrong - you want an assembled chair? Even if shipping costs more than double? (Cost to NYC & Seattle are &

for kit, & 2 for assembled chair.)

It costs too much? What would be OK (assuming we ever get out of this pandemic)?

Cushions should be included. That's tough, because the cushions have a profound effect on how the chair fits into your decor, do they need be waterproof, are there any skin allergies.

My sales pitch is too aggressive? Or idiotic, or whatever...

If you send me a message to HELP me, add DNR ("Do Not Reply") if you prefer. Usually I'd reply to say "thank you," but I personally find the eBay message system somewhat irritating (and I am not allowed to list my email address). HOBKIRK - sometimes I use Google's system. But I thank you for reading this far.

==============

Glider advantage compared to a rocker = no pinched toes or fingers!

Easy to Build - I am a woodworker, and I know what types of problems typically arise in kits.

These parts were manufactured to be easily assembled on a production line. All the bolt holes are pre-drilled and countersunk. The location the screw goes into has a pilot hole that has been pre-drilled also.

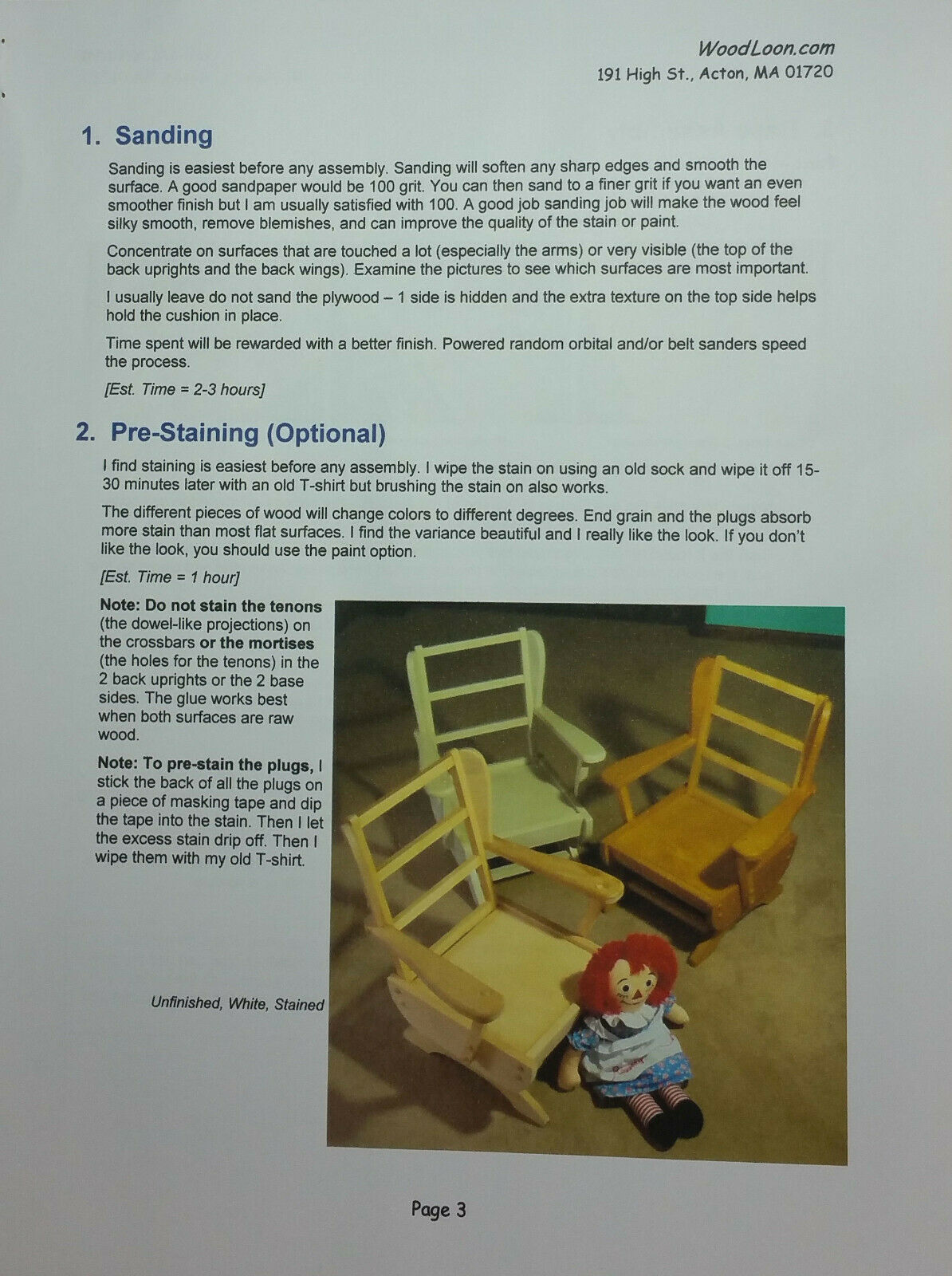

Step 1 is sand everything. Every piece comes quite smooth, but more sanding improves the finished chair. Woodworkers hate sanding! I use a hand-held tool and I do this in under 30 minutes, but I do a pretty thorough job. By hand, it might take one hour. But a perfectionist might take more. How silky do you think a child rocker should be?

If you use stain like I do, apply stain to all the wood except inside holes for screws and receptacles for tenons (glue adheres best to raw wood). You can also stain the button inserts, but I wait until after everything is assembled and the buttons have been glued in. I find it awkward to avoid getting stain on the button protrusions.

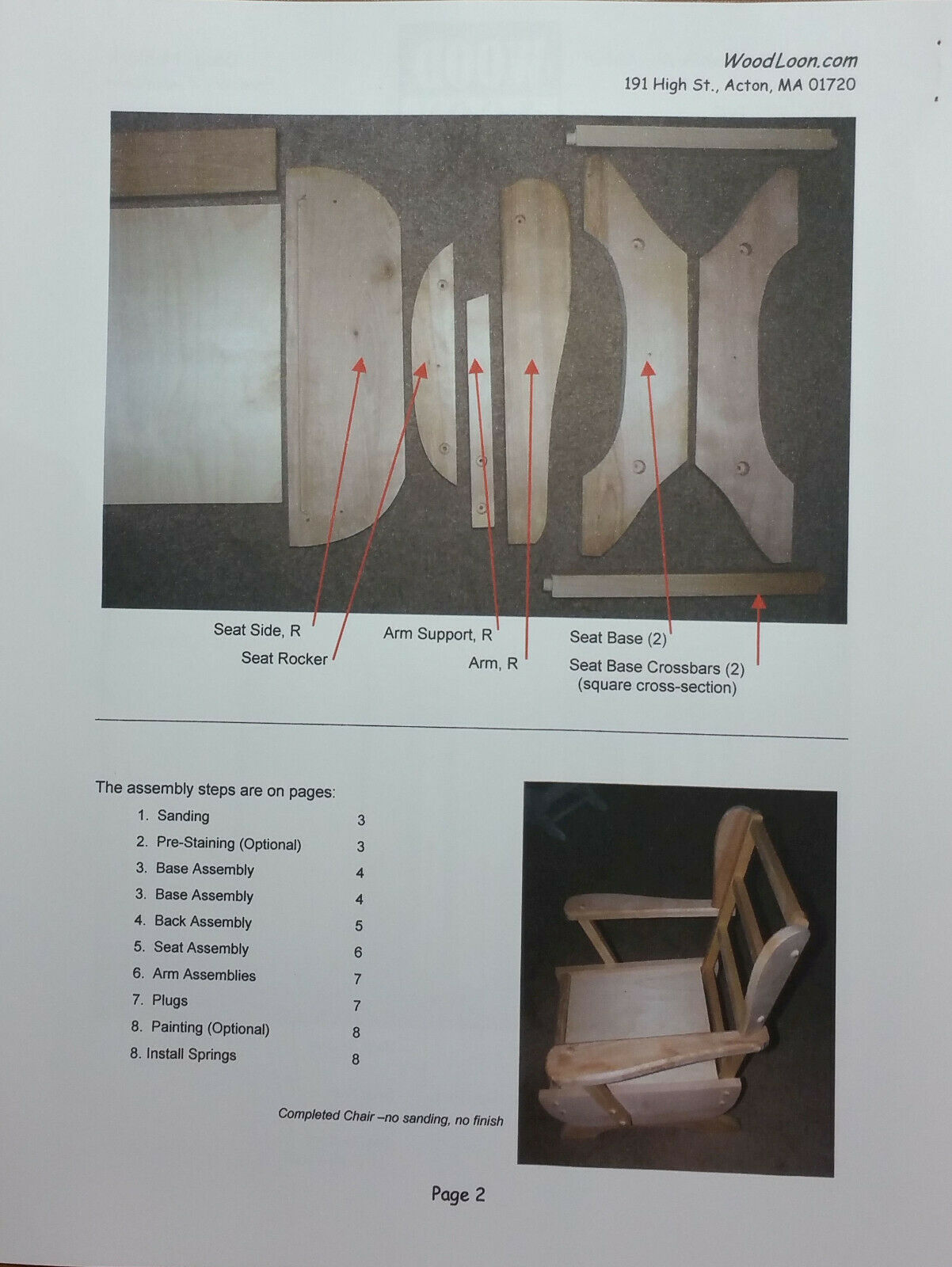

The actual assembly is pretty simple. Build the base (4 parts, glued), the back (6 parts, glued), the sides (2 parts & 2 screws each), the arms (2 parts each, screwed), assemble the seat (screw the sides to the back and the arms and insert the plywood base and attach the wings on the sides), attach the base to the seat bottom (4 eyelets and 2 springs). This takes me under an hour (plus time waiting for glue to dry (30-60 minutes).

Everything is included -

All the plugs to fill the screw holes, the correct size screws, the springs and eyelets, and sandpaper.

EXCEPT -

the wood glue and the finish (or paint). Both of these are subject to freezing and degradation. Buy fresh at Ace Hardware - Titebond .59 and Minwax stain for .59 (I prefer golden oak).

EXCEPT - cushions

Cushions -

I have a few cushions I've collected over the years, about 30 pieces of foam, one roll of Dacron (?) wrap, and a few pieces of cloth that could be used to make cushions. But that's not my thing, and that's the hangup that caused me to ignore this project. K-Mart used to carry Martha Stewart cushions that fit (designed for patio furniture mostly, I think). Contact me if you are interested in what I have, I will send you (or post) pictures of what I have.

Sturdy -

I have stuffed my 6'2", 190# body into one of these assembled and found no weaknesses. PS - That was quite a sight!

Staining vs. Painting -

I have found painting them to a level that satisfies me takes well over an extra hour compared to staining. For staining, I've been pleased with golden oak by Minwax. I've never added a poly finish coat, but I really like the feel of wood - I'm a woodworker! And if you find the stained finish unsatisfactory, you can add a protective varnish or poly or shellac top coat. Or paint it.

The box is 18" x 16" x 4 1/2" and weighs 17.2 pounds.

YOU WANT A FINISHED ROCKER! NOT A DANG KIT!

I will gladly accommodate you. They really are quick to build, including staining. In general, I could send a finished chair out one day after it is requested. I would charge for sanding, gluing, assembling, and staining. And whatever the shipping costs are.

==========

The "Story" -

I found an estate sale on the Cape where someone was selling industrial woodworking tools. I bought a metal clamping table and a few other tools.

I asked about the piles of wood and was told they were parts from a factory that was making, among other things, child rockers. We estimated there were enough parts for at least 300 rockers.

So I bought the whole pile of stuff, which turned out to be 10,000 pounds of stuff! And carted it home in several trips, organized it, and stacked the wood in my dry basement. MANY 7' high stacks of 200 (bad estimate) to over 1,000 pieces for 11 different different pieces of wood.

I had planned to make and ship the chairs, but they were so large that I thought shipping costs would be prohibitive. (Today, it would cost to NYC and 2 to Seattle.)

So I figured out how to create complete kits. I created an 8 page instruction booklet (lots of detail, color, pictures), figured out effective packaging, bought right-sized boxes, and STOPPED. That was 20 years ago!

Now that we are going to sell our house, my wife thinks I should get ride of all this stuff in our basement. So demanding! Buy one kit, or many - make my wife happy - she REALLY deserves it!