-40%

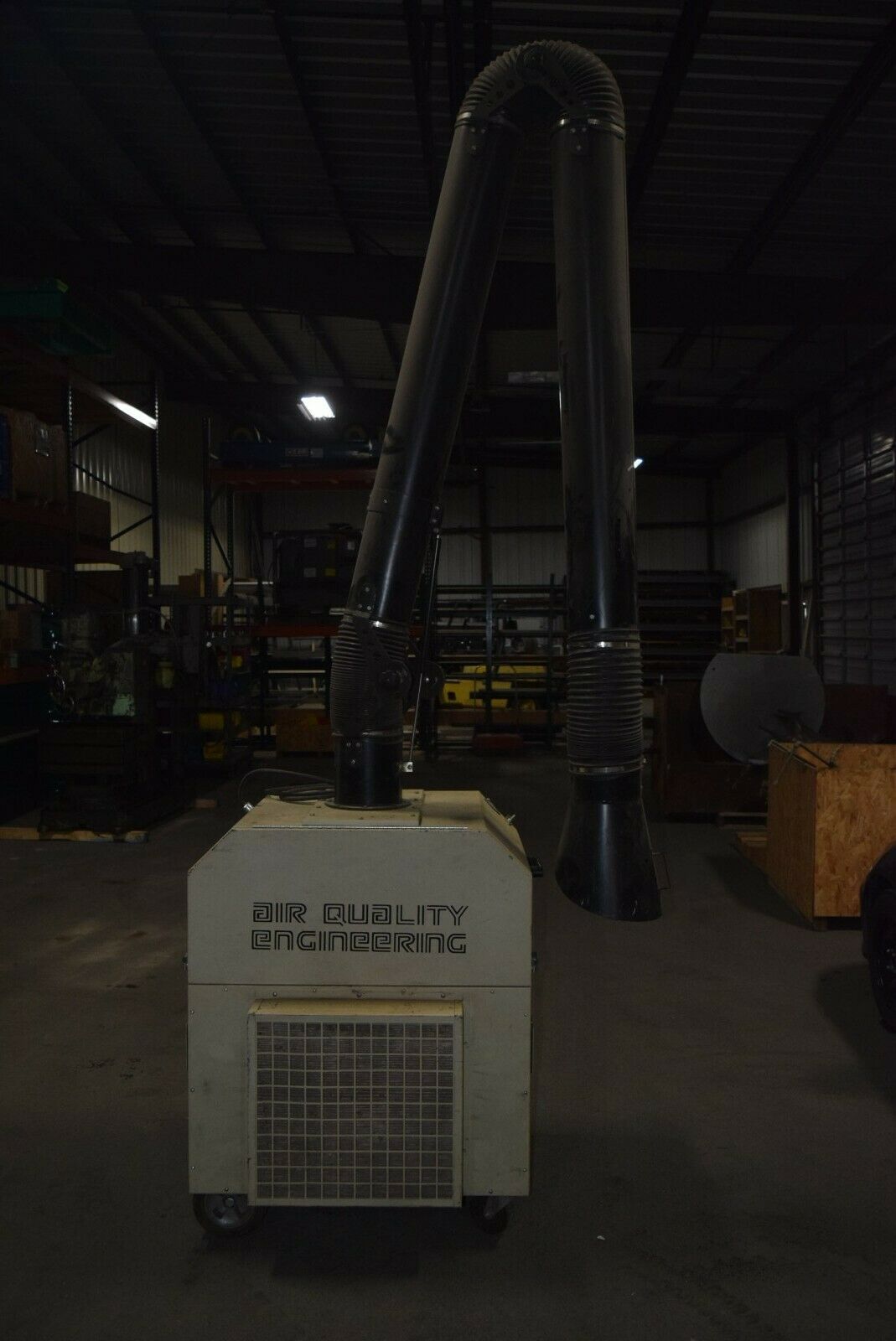

SMOKE EXTRACTOR, 1100CFM, PORTABLE, 120VAC, AIR QUALITY ENGINEERING

$ 633.6

- Description

- Size Guide

Description

MADE IN USA!Unit is in very good condition, WORKS great! The arm is flexible and 100% OPERATIONAL.

sorry the pics are bad i will get better ones when it stops raining and i can take it outside in the sun.

This is the manufacturers description.

Portable Cartridge System from Air Quality Engineering Inc. is a complete self-contained media air cleaner for use in source capture applications in industrial settings. The Model AQE2000 captures airborne contaminants such as welding smoke, grinding dust, plastic dust and other fine particles.

Principles of Operation: Airborne contaminants enter the AQE2000 through the hood/arm assembly at a rate of 1100 cubic feet of air per minute (cfm). Heavy particles are propelled downward through the venturi and into the clean out trays. Small submicron particles are then trapped within the pleats of the two MERV 15 rated cartridge filters. The cleaned air is then gently diffused out the bottom of the unit. When the filter gauge indicates that the cartridge filters are dirty, they are easily cleaned by connecting a shop air line (80-120 psi) and activating the reverse pulse system.

I WILL SHIP BUT THERE WILL BE A

0.00$

CRATING FEE TO DISASSMBLE AND BAND IT TO A PALLET,

The shipping dimensions and weight below are from the factory the arm with make the height taller even when removed from the main unit. but it give you an idea for shipping.

STANDARD FEATURES

Air volume – 1100 cfm

Reverse pulse cleaning system

Externally supported 13′ arm; Full 360° rotation

1.5 horse power motor

382 square feet of filter media

99.8% efficient at .5 micron

Large 8″ diameter front wheels

Quiet operation

SPECIFICATIONS

DIMENSIONS:

46″H x 28.5″W x 37″D

WEIGHT:

400 lbs. installed weight

450 lbs. shipping weight

ARM ASSEMBLY:

13′ long x 8″ or 6″ diameter. Externally supported arm with full 360º arm rotation.

Arm assembly incorporates a gas spring which provides easy up and down movement.

HOOD:

Spun formed aluminum hood with flange. Hood moves easily vertically and horizontally..

AIRFLOW VOLUME:

1100 cfm

MOTOR:

1.5 HP thermally protected

BLOWER:

Direct drive, backward incline

CABINET CONSTRUCTION:

16 Ga. welded CRS steel

CONTROLS:

All models include control circuitry and thermal protection.

POWER:

120V/60 hz/14 amp running or 208-240V/60 hz/8 amp running.

Ten-foot power cord with molded plug standard on single phase models.

FINISH:

Durable powder coat paint

FILTRATION:

Two high efficiency cartridge filters: 12 3/4″ diameter x 22″

382 sq. ft. total, 99.8% efficient at .5 micron (MERV 15)

FILTER ACCESS:

Hinged side door

FILTER CLEANING:

Self-Cleaning Reverse Pulse Jet System which utilizes a one inch diaphragm valve.

Requires 80-120 psi of shop supplied compressed air. 1/4″ NPT female fitting is provided to accept field installed quick connect.

FILTER GAUGE:

Dirty filter gauge indicates pressure up to 10″ WG

NOISE LEVEL:

73 dBa at 6′